ball mill classifier

ball mill classifier is an efficient tool for fine powder grinding. ball mill classifier is often used for grinding silica sand. The ball mill classifier is used to grind many kinds of mine and other materials, or to select the mine. ball mill classifier is widely used in building material, chemicalindustry, etc. There are two ways of grinding: the dry way and the wet way. It can be divided into tabular type and flowing type according to different expelling mine. Shanghai Zenith is a famous ball mill classifier manufacturer.

ball mill classifier Features:

1.Newest structure

2.Easy maintenance and operation

3.Durable wearing parts

4.Low operating cost

5.Big and fine grinding ratio

6.Both dry and wet grinding types available

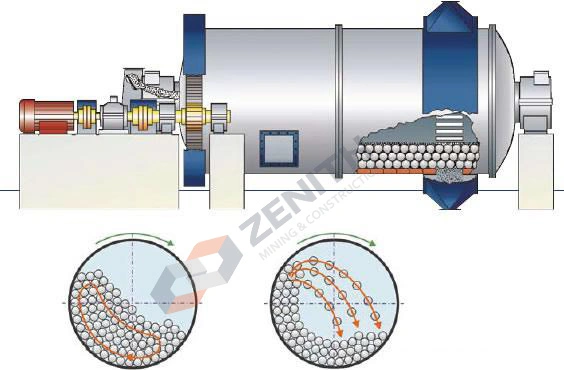

ball mill classifier Principle:

1.To use the ball mill, the material to be ground is loaded into the neoprene barrel that contains grinding media.

2.As the barrel rotates, the material is crushed between the individual pieces of grinding media that mix and crush the product

into fine powder over a period of several hours.

3.The longer the ball mill runs, the finer the powder will be.

4.Ultimate particle size depends entirely on how hard the material you're grinding is, and the time how long the ball mill runs.

ball mill classifier parameters:

ball mill classifier parameters:

| Specification (Dia×Length) | Rotating speed (r/min) | Feed size (mm) | Capacity (t/h) | Grinding media load (t) | Main motor | Main reducer | Weight(t) | |||

| Model | Power(kw) | Rotating speed (r.p.m) | Model | Reduction ratio | ||||||

| φ2.4×8 | 20.91 | ≤25 | 25~28 | 39~42 | JRQ1512-8 | 570 | 740 | ZD80-9 | 5 | 76.4 |

| φ2.4×10 | 20 | ≤25 | Open circuit 27~30 Closed circuit 38~40 | 50 | YR710-8/1180 | 710 | 740 | JDX630 | 5.6 | 111 |

| φ2.4×11 | 21 | ≤25 | Open circuit 41~42 Closed circuit 46~48 | 62~65 | YR800-8/1180 | 800 | 740 | MBY710 | 6.3 | 125 |

| φ2.4×12 | 21 | ≤25 | Open circuit 40~42 Closed circuit 45~48 | 63~65 | YR800-8/1180 | 800 | 740 | MBY710 | 6.3 | 127 |

| φ2.4×13 | 21.5 | ≤25 | 48~51 | 68~72 | YR800-8/1180 | 800 | 740 | MBY710 | 6.3 | 131 |

| φ2.6×8 | 20 | ≤25 | 30~35 | 54 | YR630-8/1180 | 630 | 740 | JDX630 | 5.6 | 135 |

| φ2.6×10 | 20.91 | ≤25 | 45~46 | 80 | YR1000-8/1180 | 1000 | 740 | JDX710 | 6.3 | 136 |

| φ3×9 | 19.13 | ≤25 | 50~55 | 76~80 | YR1000-8/1180 | 1000 | 740 | JDX800 | 6.3 | 145 |

| φ3.2×7 | 18.25 | ≤25 | 50~52 | 58 | YR1000-8/1180 | 1000 | 740 | MBY800 | 6.3 | 140 |

| φ3.2×9 | 18.3 | ≤25 | 60~70 | 90 | YR1250-8/1430 | 1250 | 740 | JDX900 | 7.1 | 175 |

| φ4.6×10+3.5 | 15 | ≤25 | 195 | 190 | 3550 | 740 | JS150-B-F | 476 | ||